Generations of Helmets

The structure:

The ![]() technology liner is a shock absorbing foam liner for safety helmets that incorporates cone-shaped structures within the thickness of the helmet liner.

technology liner is a shock absorbing foam liner for safety helmets that incorporates cone-shaped structures within the thickness of the helmet liner.

The revolutionary shock absorbing ![]() technology liner consists of two layers.

technology liner consists of two layers.

The ![]() layer (i.e., the inner layer) consists of four different regions of cones or triangular based pyramids made of expanded polystyrene foam of varying low densities which is designed to meet the different weaknesses/strengths of the skull.

layer (i.e., the inner layer) consists of four different regions of cones or triangular based pyramids made of expanded polystyrene foam of varying low densities which is designed to meet the different weaknesses/strengths of the skull.

The overlying layer (i.e., the outer layer) is made of expanded polystyrene foam of single density which is of higher density compared to the ![]() layer.

layer.

The generations:

1st Generation –

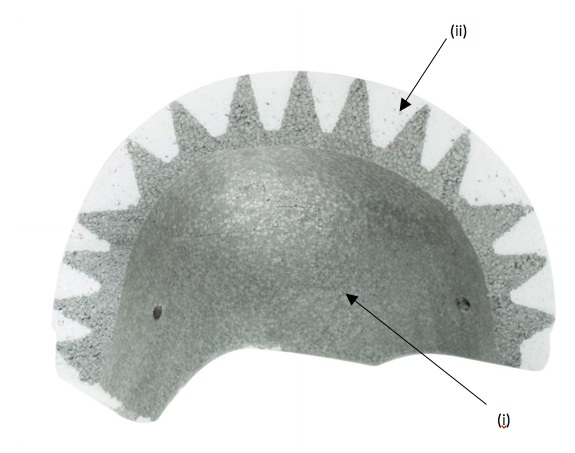

Photo 1: Shows a ![]() technology liner = (i)

technology liner = (i) ![]() layer + (ii) overlying layer

layer + (ii) overlying layer

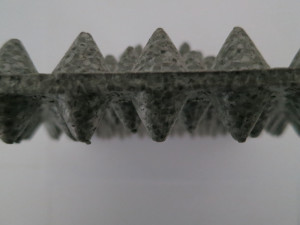

Photo 2: Shows a ![]() layer with cones

layer with cones

Photo 3: Shows a cone exposed in

a test sample of a ![]() technology liner

technology liner

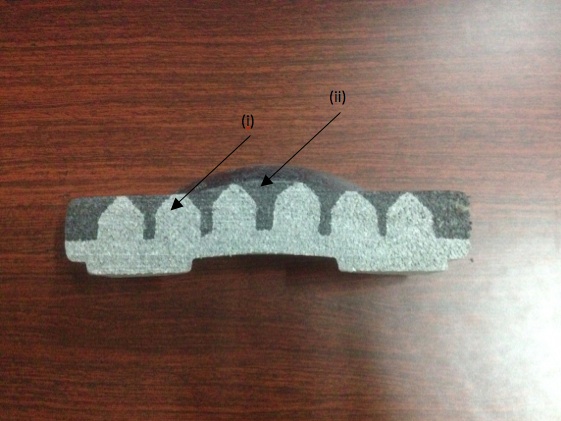

Photo 4: Shows samples of 1st generation

![]() technology liners and

technology liners and ![]() layers

layers

2nd Generation – (i) triangular base pyramids (ii) cones facing inwards

Photo 5: Shows a ![]() layer with triangular based pyramids

layer with triangular based pyramids

Photo 6: Shows a ![]() layer as an outer layer with cones facing inwards.

layer as an outer layer with cones facing inwards.

The inner layer (not shown) is the overlying layer.

Photo 7: Shows the comparison between

1st and 2nd generation ![]() layers

layers

3rd Generation – double

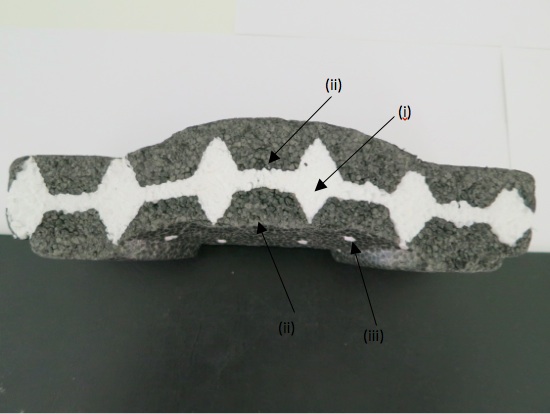

Photo 8: Shows a test sample of a double

Photo 8: Shows a test sample of a double ![]() technology liner =

technology liner =

(i) double ![]() layer +

layer +

(ii) overlying layers (inner and outer).

The white dots (iii) are apices of cones

Photo 9: Shows a test sample of a double ![]() layer

layer

4th Generation – Super

Coming soon

Other Structures Tested – Pencil and Funnel Shaped

Photo 10: Shows a test sample of a pencil shaped ![]() layer

layer

Photo 11: Shows a test sample of a pencil shaped ![]() technology liner = (i) pencil shaped

technology liner = (i) pencil shaped ![]() layer + (ii) overlying layer

layer + (ii) overlying layer

Photo 12: Shows a test sample of a funnel shaped ![]() layer

layer

The Benefits of  technology in more detail

technology in more detail

- Absorb an impact force more effectively:

- directs impact energy sideways away from the brain thereby lowering g-forces to the head

- different foam densities (multi-densities) absorb different levels of impact forces thereby reducing the risk of concussion at low level impacts and more severe head injuries at high level of impacts

- A lighter helmet (lower mass helmet): to reduce rotational acceleration of the head during impact

- Segmentation/zoning: to allow the combinations of high and low density foam to be placed close to the vulnerable areas of the skull (child’s skull and adult skull’s) of different thicknesses and strengths

- Enable the use of thinner liners

“For each different size (i.e., S, M, L, XL) helmet incorporating ![]() technology, manufactured and sold under different brand names, has its own density signature comprising of up to five different densities.”

technology, manufactured and sold under different brand names, has its own density signature comprising of up to five different densities.”

~ Don Morgan